Pick Up Product DI@SSET

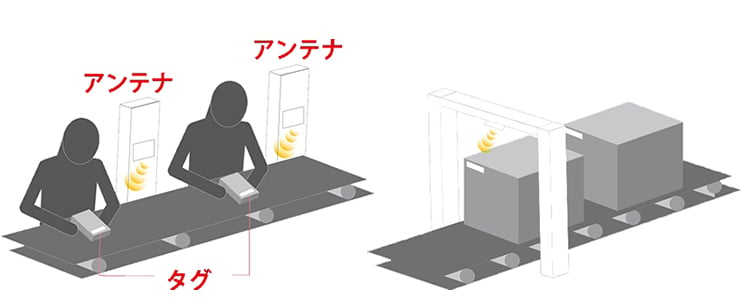

UHF RFID systems

We offer an optimum RFID (IC tag) system to suit your scale of deployment and budget from applications provided by a number of our partners.

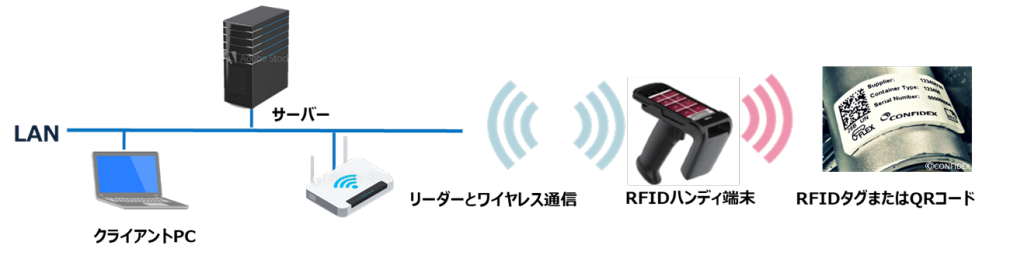

(1) Hand-held RFID system DI@SSET family

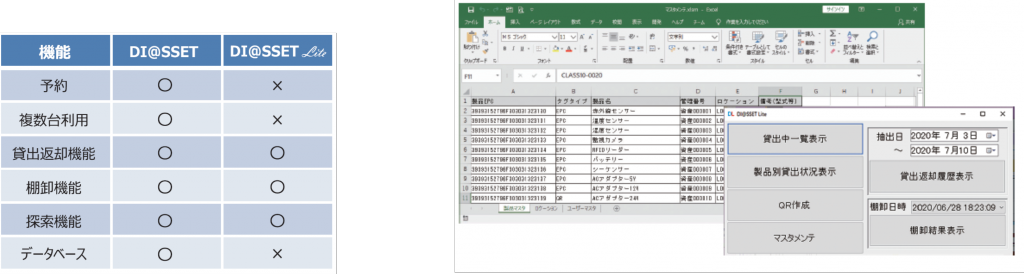

①DI@SSET asset and equipment management system

This is a hand-held RFID reader/writer for a fixed asset and equipment management system.

The RFID reader can manage borrowing and returning assets/equipment and users can make a reservation for borrowing via a web browser.

A search function for RFID tags significantly reduces the enormous amount of time required for inventory management.

Major applications include management of IT assets (blade servers) and storage media at data centers, management of equipment and paintings at a general affairs department, management of PCs in terms of information security, and management of measuring instrument and molds in the manufacturing field.

② DI@SSET Lite asset and equipment management system

This configuration consists only of a PC and a hand-held reader, and is simpler than DI@SSET. This system lets users borrow, return, take inventory, and search.

This package is ideal for users who would like to introduce a management system using RFID tags or QR codes on a trial basis, for only one department, or for other small-scale deployment.

③ DI@SSET Spare Parts Management Lite spare parts management system

You cannot run a manufacturing business without managing spare parts and consumables used on production lines.

However, there may be times when there is no stock left when you would like to replace parts.

You may also have to spend hours looking for them because you don’t know where they are stored.

A large number of items makes inventory time consuming, too.

DI@SSET SPM Lite enables the following:

- RFIDs drastically reduce the time required for inventory management

- You can identify who has taken out how many items, which lets you assign costs to each department

- You can affix an RFID tag on a container for assets that are too small in terms of their value or size to have their own RFID tags, which enables:

“quantity management” and “remaining quantity management”

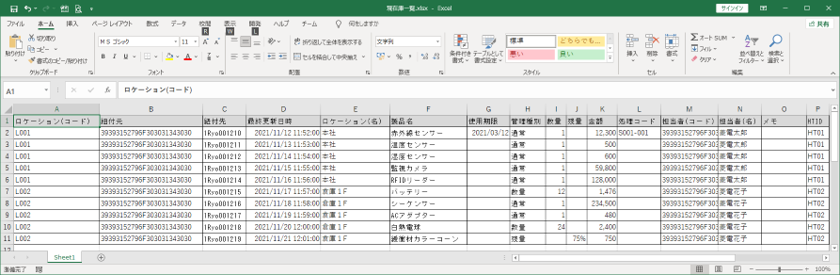

- Inventory management can be done using Excel that everyone is familiar with

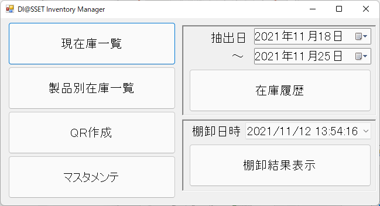

④"DI@SSET Inventory", a multiple read & transfer tool for those who want to introduce RFID

You want to try out RFID systems to improve efficiency and automation, but the cost of software development can be a bottleneck.

This tool makes it possible to introduce an RFID system easily and inexpensively.

・Read, encode, search, inventory, and tie/untie functions are implemented.

・Record "who," "when," "who," "where," "what," and "how" (4W1H).

・Transmits data to the management terminal via Bluetooth or USB connection

・Easy to operate with an Excel-based interface

・Linkage to fixed gate systems is possible (optional).

DI@SSET Inventory Mobile

DI@SSET Inventory Manager

Note. Please inquire here for details of DI@SSET family systems and their prices.

Note. DI@SSET is a registered trademark of RYODEN Corporation.

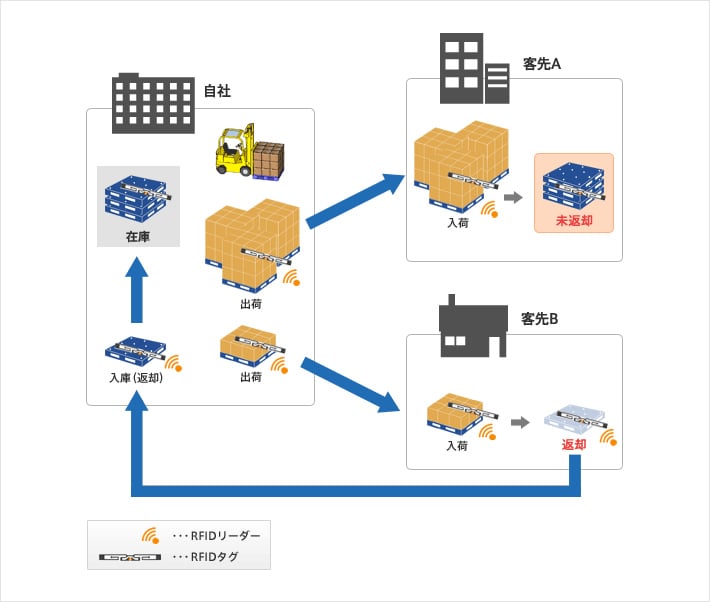

(2) Reusable container management system

In automotive and other manufacturing industries, large quantities of reusable containers (e.g. pallets, reusable boxes, cart cages, and Ori-con) are used across various companies and locations.

However, due to the lack of understanding about the inventory and usage status of reusable containers, there are often shipping issues such as insufficient dedicated containers causing an inability to ship products, as well as other issues such as loss and holdup. As a result, many unnecessary purchases of reusable containers are being made.

Our cloud system (ATLAS-Things) offers a secure environment anywhere in the world, anytime, significantly reducing your system building and operational costs, while lowering initial deployment expenses.

(3) Process management system

1) Process management (e.g. coating) Process management for objects that travel through a predetermined position such as a position on a belt conveyor. By attaching RFID tags to the reusable carts, an environment can be established with only an initial investment.

An example at a coating process is depicted below.

2) Process management (work)

Temporarily affix a tag on a product with a magnet (temporarily affix it on a product sheet) and also let the worker have a tag. This way, you can keep a record of when (for how long) and what work is done by who.