Robots

We deal in industrial robots, collaborative robots, and autonomous mobile robots (AMR).

List of products related to Robots from FA Systems

-

The “right hand man” for FA, equipped with advanced technology - With high-speed, high-precision basic performance and intelligent sensors, MELFA Smart Plus enables automation with a high degree of difficulty. Additionally, its high compatibility with sequencers and other FA products ensures thorough ease of use.

-

Easier, more user-friendly, and more flexible - Mitsubishi Electric’s "ASSISTA" collaborative robots work with and alongside humans in busy production sites.

-

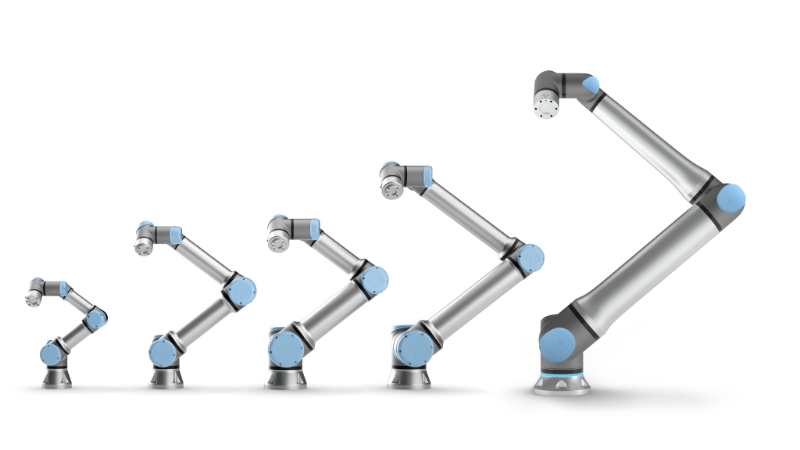

We focus on providing safe, flexible, and easy-to-use 6-axis industrial robot arms for companies of all sizes. UR e-Series robots are equipped with various functions to fulfill customer requests. Extensive lineup: UR20, UR16e, UR10e, UR5e, UR3e Compatible with direct teaching method Operational after 90-minute online training Stopping operating when sensing of 100N~250N (50N~250 N only for UR3e) Seventeen adjustable safety features available

-

Elite Robots are cooperative robots that comprehensively embody the integration of control technology, servo technology, encoder technology, mechanical technology, structural technology, and industrial design technology. They can be used in a wide range of applications, including 3C assembly, logistics sorting, healthcare, education, new retail, and more.

-

We propose over 1,000 combination solutions, from pneumatic, hydraulic and manual, to magnetic types. You can flexibly select the solution that best suits your work.

-

We offer a wide variety of vacuum equipment for both automated and manual transportation, as well as clamping. We contribute to productivity improvement and cost reduction in the manufacturing industry by providing machines that absorb and automatically transport various products produced in factories, handling systems that support manual material loading and logistics transportation, and clamping systems that adsorb and hold materials before processing.

-

With ROBOTIQ tools and know-how, the introduction of collaborative robots becomes simple, contributing to rapid production start-up. We support the manufacturing industry with a strong global network of robotics experts.

-

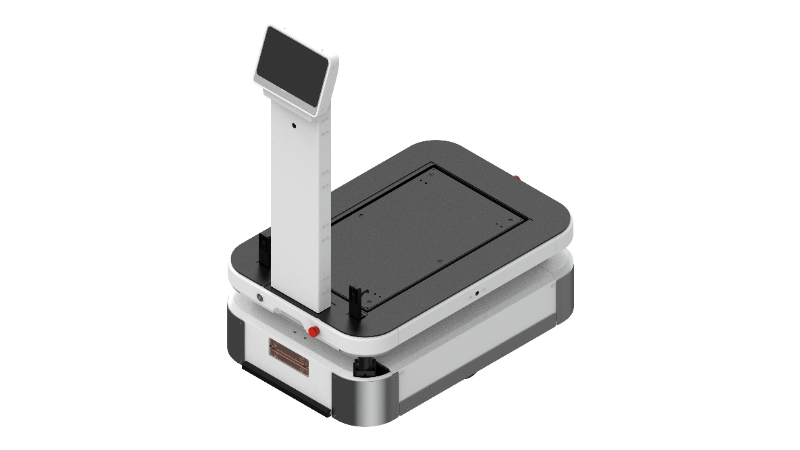

ForwardX’s autonomous mobile robots (AMRs) utilize information not only from LiDAR scanners, inertial measurement units, and wheel encoders, but also from visual sensors such as 2D and 3D cameras to provide 360° obstacle avoidance. The lineup includes products with load capacities from 300 to 1,200 kg. Furthermore, the management software FleetManager f(x) not only manages up to 200 AMRs, but also serves as a bridge between your existing equipment management system and our robot management system.

-

Indoor transportation and material handling are key to the success of logistics. The MiR Series of autonomous mobile robots (AMRs) optimizes these workflows to run smoothly.

-

In consideration of complaints emerging from production sites amid the increasing adoption of collaborative robots, such as “Standard robot mounts are expensive,” “The height cannot be changed,” “They are heavy,” and “Not user-friendly,” we have released new robot mounts from the user's standpoint. To address the rapidly increasing number of robot models, we adopted a bolt-assembly specification, rather than a cast integral design. By manufacturing only the necessary parts tailored to the robot, we have established specifications that are compatible with a variety of robots.